ZORGON (jiangsu) Automation Technology Co., Ltd.

ZORGON (jiangsu) Automation Technology Co., Ltd.

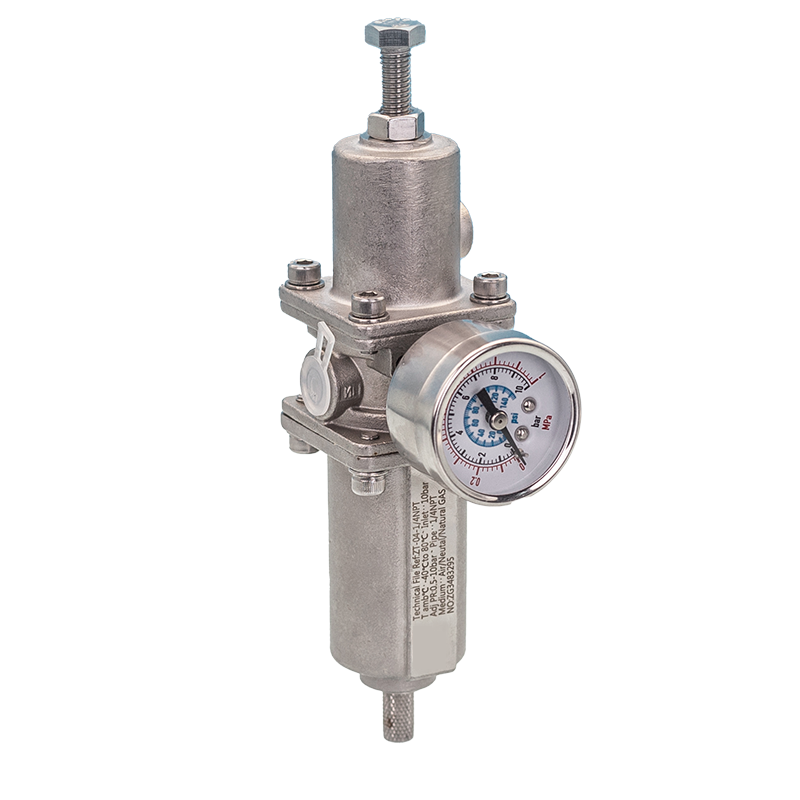

The stainless steel air filter consists of a multi-element filter element, a shell, a backwash mechanism and a pressure difference controller.

When impurities in the air filter accumulate on the surface of the filter element, causing the inlet and outlet pressure difference to increase to the set value, or the timer reaches the predetermined time, the electric control box sends a signal to drive the backwashing mechanism. When the inlet of the backwash suction cup is opposite the inlet of the filter element, the blowdown valve opens. At this point, the system releases pressure and drains water. There is a negative pressure area between the suction cup and the inside of the filter element where the relative pressure is lower than the water pressure outside the filter element, forcing part of the clean circulating water to flow from the outside of the filter element to the inside of the filter element, and the impurity particles are absorbed by the water on the inner wall of the filter element into the pot with the water, and discharged from the drain valve. The specially designed filter screen produces a spray effect inside the filter element, and any impurities can be washed away to smooth the inner wall. When the filter inlet and outlet pressure difference returns to normal or the timer set time ends, the material does not stop flowing during the whole process, the backwashing water consumption is small, and continuous automatic production is realized.

CONTACT

Enter your Emall or phone number and we will contact you as soon as possible. ZORGON As a professional automatic control equipment manufacturer in the UK, with the first solenoid valve came into being, after decades of continuous innovation and development. With the transfer of...

ZORGON As a professional automatic control equipment manufacturer in the UK, with the first solenoid valve came into being, after decades of continuous innovation and development. With the transfer of... Any question or request?

Click below, we’ll be happy to assist. CONTACT