ZORGON (jiangsu) Automation Technology Co., Ltd.

ZORGON (jiangsu) Automation Technology Co., Ltd.

Nowadays, the skill of liquid level measurement is the fundamental skill of process control management in chemical, chemical, environmental and related industries. Pepplus helps users deal with special measurement and control problems, and can accurately detect the liquid level of any medium.

Limit detection switch switches signals when the medium reaches the set height, exceeds the set value or is lower than the set value. The setting values (VDI/VDE Directive 3519) are based on the height of the device.

Operation mode of tuning fork liquid/material level measuring instrument: two tuning forks are oscillated by piezoelectric devices in operation. The tuning fork has a fixed frequency of oscillation in the air. When liquid is encountered, the tuning fork frequency and amplitude change. The circuit detects these changes and produces a switching signal.

When measuring a limit with an oscillating limit switch, place the rod or tuning fork in oscillation. If the oscillating probe touches the medium, the oscillation is altered and the oscillating limit switch announces an on-off command. Oscillating limit switches are used as overflow protection devices or no-load reporters in liquids and in granular or powdered solids.

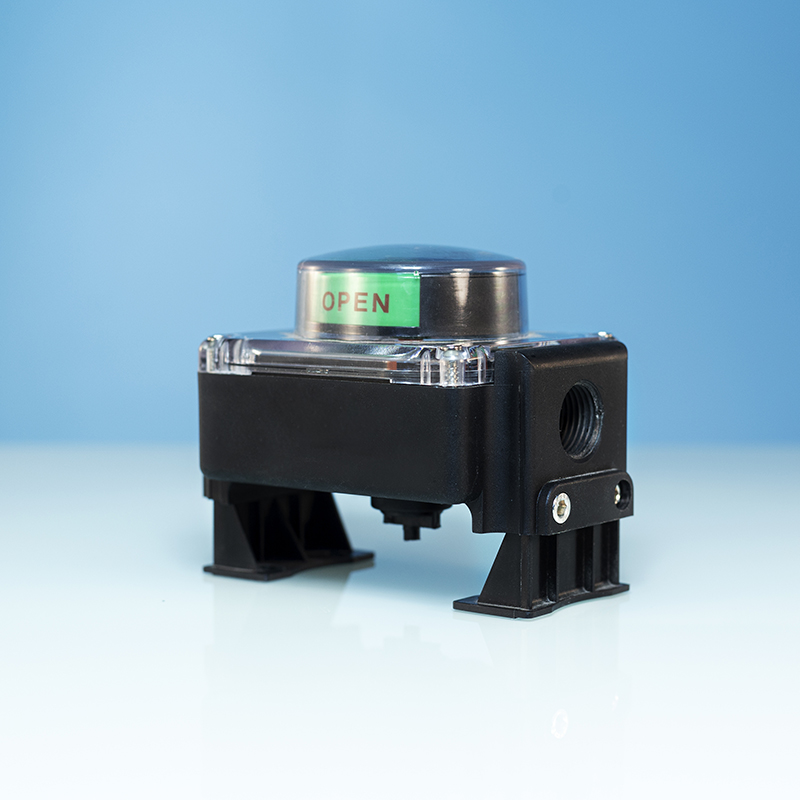

The device is a consolidated silo horizontal limit switch -- granular or coarse-grained, non-fluidized solids. The variety of designs means the range of the device is wide. Flammable hazard zones can be used in dust.

Typical applications: grain, coffee beans, sugar, animal feed, rice, detergent, dye powder, chalk, plaster, cement, sand, plastic pellets.

Product features:

● Liquid sanitary limit switch

● A lot of process connection choice: universal

● Various electronic modules (such as relays, thyristor signal output) : correct connection of each process control system

● No calibration: fast and low cost start

No mechanical moving parts: no protection, no wear, long service life

● Monitoring whether the oscillation fork is damaged: ensure the function

● PROFIBUS PA protocol: debugging and protection is fast and convenient

● Fit EHEDG's process connection

● SIL 2 in accordance with IEC 61508

CONTACT

Enter your Emall or phone number and we will contact you as soon as possible. ZORGON As a professional automatic control equipment manufacturer in the UK, with the first solenoid valve came into being, after decades of continuous innovation and development. With the transfer of...

ZORGON As a professional automatic control equipment manufacturer in the UK, with the first solenoid valve came into being, after decades of continuous innovation and development. With the transfer of... Any question or request?

Click below, we’ll be happy to assist. CONTACT