ZORGON (jiangsu) Automation Technology Co., Ltd.

ZORGON (jiangsu) Automation Technology Co., Ltd.

Solenoid valve installation precautions;

1, before installation should refer to the product manual, whether it meets your requirements.

2, the pipeline should be washed before use, and the filter should be installed if the medium is not clean to prevent impurities from hindering the normal operation of the solenoid valve.

3. The solenoid valve after a long time of disuse should be easy to use after clearing the condensate; When disassembling and cleaning, the parts should be placed in order and then restored to the original state.

4, the solenoid valve is generally one-way work, can not be reversed, the arrow on the valve is the direction of movement of the pipeline fluid, must be consistent.

5, the solenoid valve should be heated when it is re-working in an icy place, or set up insulation measures.

6, the solenoid valve installation is generally horizontal, the coil is vertical upward, some products can be arbitrarily installed, but when the conditions permit, the best vertical to increase the service life.

7, the electromagnetic coil lead wire (connector) after the connection, should confirm whether it is firm, the contact of the connecting electrical components should not shake, loose will cause the solenoid valve does not work. Continuous production of the solenoid valve, it is good to use bypass, easy maintenance, does not affect the production.

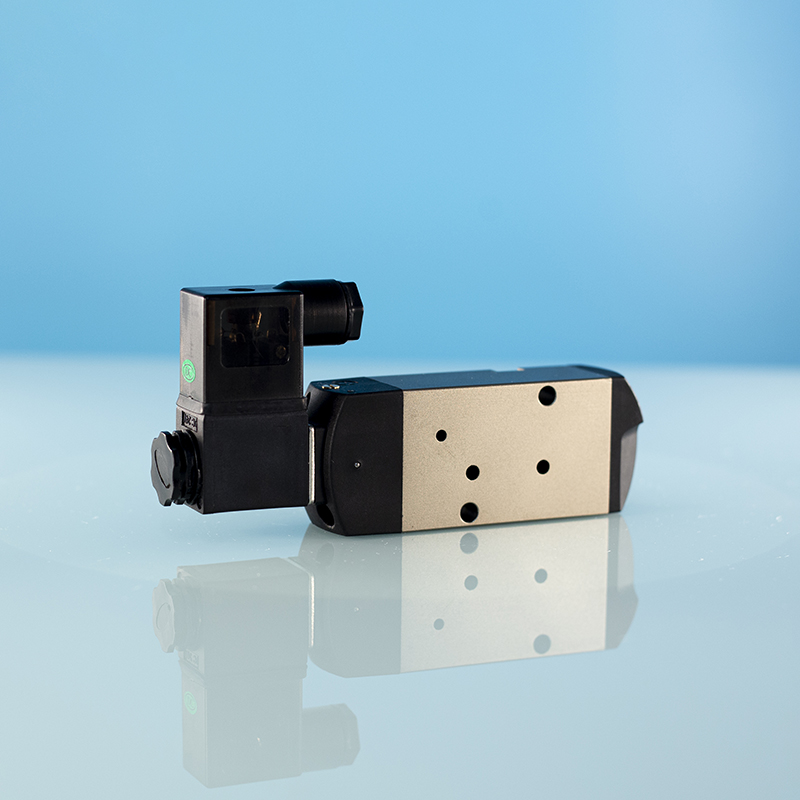

Solenoid valve is divided into direct acting and pilot type two structural principles, the safe design of three-dimensional sealing structure can flexibly choose different sealing materials, the valve can reach zero leakage. High pressure solenoid valve brass high pressure solenoid valve and stainless steel high pressure solenoid valve. Control of various pipeline lines.

CONTACT

Enter your Emall or phone number and we will contact you as soon as possible. ZORGON As a professional automatic control equipment manufacturer in the UK, with the first solenoid valve came into being, after decades of continuous innovation and development. With the transfer of...

ZORGON As a professional automatic control equipment manufacturer in the UK, with the first solenoid valve came into being, after decades of continuous innovation and development. With the transfer of... Any question or request?

Click below, we’ll be happy to assist. CONTACT