ZORGON (jiangsu) Automation Technology Co., Ltd.

ZORGON (jiangsu) Automation Technology Co., Ltd.

According to the specific situation, the appropriate air filter is reasonably selected, and the selection principle is as follows:

1、 According to the cleanliness and purification standards of indoor requirements, determine the efficiency of the final stage of the air filter, and reasonably select the combined stage and efficiency of the air filter at all levels. If the room requires general purification, the initial effect filter can be used; If the indoor requirements of medium purification, it should use the primary effect and medium effect two-stage filter; If the indoor requirements of ultra-clean purification, it should use the initial effect, medium effect and high effect three-stage purification filter, and should be reasonable and properly match the efficiency of all levels of filter, if the efficiency of the adjacent two stages of filter is too large, then the former filter can not play a protective role in the last level of filter.

2. Correctly measure the dust content and dust particle characteristics of outdoor air. Because the filter is to filter and purify the outdoor air into the room, the dust content of the outdoor air is a very important data. Especially in the multi-stage purification filtration treatment, the selection of the pre-filter should be decided after considering the use of the environment, spare parts cost, operation energy consumption, maintenance and supply.

3. Correctly determine filter characteristics. The characteristics of the filter are mainly filtration efficiency, resistance, penetration rate, dust capacity, filtration wind speed and processing air volume. Under the conditions allowed, should be as far as possible to choose high efficiency, low resistance, large dust capacity, moderate filter wind speed, large processing air volume, easy to manufacture and install, low price filter. This is the economic analysis needs to consider the one-time investment and secondary investment and energy efficiency ratio when selecting air filters.

4. Analyze the properties of dust-containing gases. The properties of dust-containing gases related to the selection of air filters are mainly temperature, humidity, acid-base and the number of organic solvents. Because some filters are allowed to be used at high temperatures, while some filters can only work at room temperature and constant humidity, and the amount of acid-base and organic solvents in dusty gases has an impact on the performance and efficiency of air filters.

Performance index

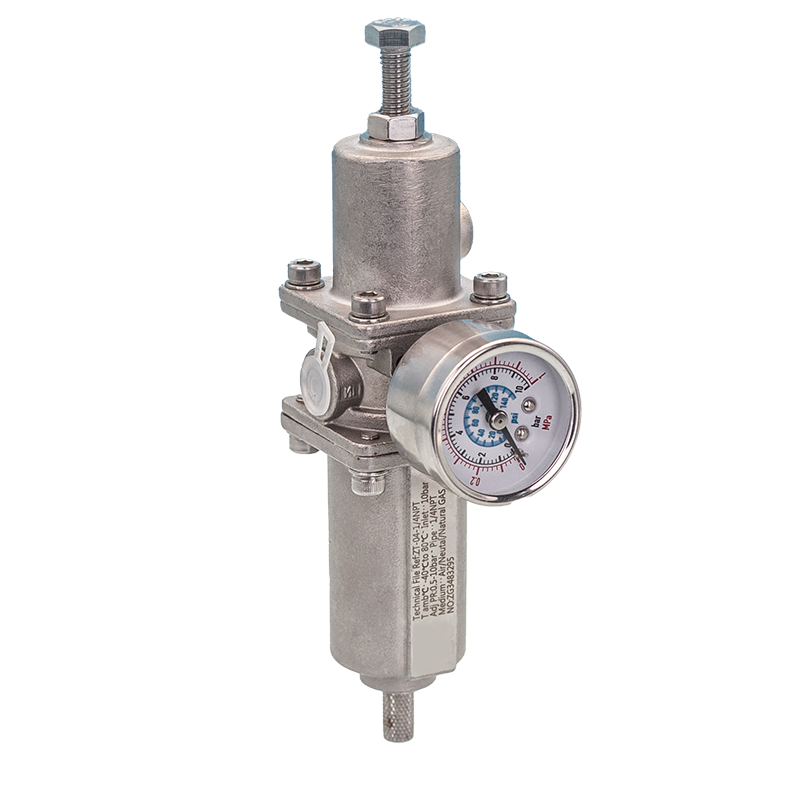

1, filtration accuracy:

The large diameter of the impurity particles that are allowed to pass through. The key to affecting the filtration accuracy is the filter element, and different filter elements can be selected according to the needs of the following components to achieve the corresponding filtration accuracy.

2. Flow characteristics:

It refers to the relationship between the air flow through the filter and the pressure drop at both ends of the filter under a certain inlet pressure. In actual use, it is selected within the range of pressure loss less than 0.03MPa. In the air filter, the main factors affecting the flow characteristics are the body and the filter element.

3, water distribution efficiency:

Refers to the proportion of separated water to the water in the air intake. It is generally required that the water separation efficiency of the air filter is not less than 80%. The main factor affecting the water separation efficiency is the baffle.

Air filters have different filtration efficiency with different concentrations.

(1) The dust concentration of the weight efficiency is expressed by the mass concentration (g/m3)

(2) Counting efficiency Dust concentration is expressed by counting concentration (pc/L)

(3) Sodium flame efficiency takes sodium chloride solid particles as the dust source. The concentration of sodium chloride particles was measured by photoelectric flame photometer. The sodium flame efficiency is comparable to the counting efficiency.

4, filter resistance:

The resistance of the new filter at the rated air volume is called the initial resistance; At the rated air volume, the resistance when the dust capacity of the filter is large enough to require cleaning or replacement of the filter material is called the final resistance.

5, filter dust capacity:

At the rated air volume, when the resistance of the filter reaches the final resistance, the total mass of the dust particles contained by it is called the dust capacity of the filter.

Selection principle

CONTACT

Enter your Emall or phone number and we will contact you as soon as possible. ZORGON As a professional automatic control equipment manufacturer in the UK, with the first solenoid valve came into being, after decades of continuous innovation and development. With the transfer of...

ZORGON As a professional automatic control equipment manufacturer in the UK, with the first solenoid valve came into being, after decades of continuous innovation and development. With the transfer of... Any question or request?

Click below, we’ll be happy to assist. CONTACT